The best QM solutions for

your company

The best QM Solutions for your Company

success stories

Find out first-hand how companies from industry and the service sector use roXtra to design their quality management systems (QMS) efficiently and in compliance with standards. Whether ISO 9001, industry-specific quality standards or comprehensive risk management - roXtra offers customized solutions for transparent, digital and compliant implementation of quality management. With our QM software for industry and services, processes can be controlled efficiently, audits and certifications facilitated and the requirements of various standards reliably fulfilled.

In our blog, you can find out more about certification and re-certification, successful implementation and practical application examples from the industry.

Get advice now

Get to know roXtra in a non-binding and free online presentation.

Industry QM software: Effective document control with roXtra

In the production and service sectors, quality, efficiency and conformity to standards are crucial for long-term success. Certifications such as ISO 9001 or industry-specific standards require a structured and efficient quality management system (QMS).

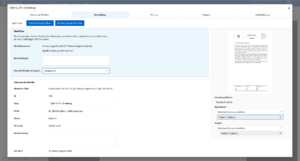

The roXtra document control module considerably simplifies the management of your QM documentation - from process descriptions to safety guidelines and work instructions. The digital document management system (DMS) supports you in controlling the entire life cycle of your documents and efficiently implementing legal and company-specific requirements.

Your advantages with roXtra in the area of document control:

- Individual approval workflows - adaptable to your processes and industry-specific requirements.

- Audit-proof versioning - automatic storage, archiving and traceability.

- Standard-compliant document management - Supports standards such as ISO 9001, IATF 16949 or industry-specific guidelines.

Digitize and automate processes - efficiently and in compliance with standards

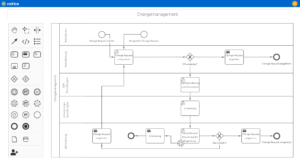

Optimize your internal processes with roXtra Processes and make your quality management in industry and services more efficient. Thanks to the graphical modeling according to BPMN 2.0, rules, responsibilities and tasks for various processes and forms - such as test reports, approval procedures or audit processes - can be easily defined and controlled.

With roXtra, you can automate your QM processes, ensure transparency and meet standard requirements - ideal for production, manufacturing and services.

With the Flowchart Designer, you can easily create flowcharts, organization charts or mind maps to make processes clear and easy to understand for everyone involved. This facilitates process control and improves collaboration throughout the company.

With the Flowchart Designer, you can easily create flowcharts, organization charts or mind maps to make processes clear and easy to understand for everyone involved. This facilitates process control and improves collaboration throughout the company.

Advantages of process management with roXtra:

- Transparency and clarity - control of complex processes such as CAPA processes, complaint management or approval procedures.

- Continuous improvement (CIP) - optimize processes and sustainably increase efficiency.

- User-friendliness - Intuitive design and easy adaptation to your company-specific requirements.

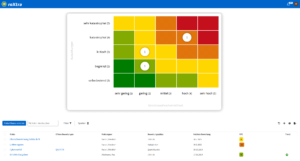

Efficient risk management for industry and services with roXtra risks

With roXtra Risks, you can optimize your risk management, minimize operational hazards and increase process reliability in production and services. The software enables central risk analysis, reduces the workload and supports compliance with important standards such as ISO 31000 and ISO 9001. Risks - from operational interruptions to quality defects and compliance violations - can be identified, evaluated and minimized through targeted measures. This allows you to sustainably improve safety, quality and efficiency and meet regulatory requirements.

Your benefits with roXtra risks

- Central risk analysis - record, evaluate and manage all risks at a glance.

- Compliance with relevant standards - support for ISO 31000, ISO 9001 and industry-specific requirements.

- Sustainable risk minimization - proactive measures to improve quality and operational safety.

Effective audit management with roXtra audits

Structured audit management is essential for reviewing quality processes, identifying deviations and driving continuous improvement. With roXtra Audits, you can increase the effectiveness and transparency of your internal audits as well as the auditing of management systems in accordance with ISO 19011 and other standards.

Whether ISO 9001, ISO 14001 or industry-specific standards - with roXtra Audits you can plan, document and manage audit processes efficiently and in compliance with regulations. The software helps you to identify potential for improvement, implement measures directly and ensure seamless traceability.

Your advantages with roXtra Audits:

- Efficiency and transparency - start and document immediate, corrective and preventive measures directly in the audit process.

- Systematic implementation - location-independent access to your question catalog, also available offline.

- Optimized planning: Maintain an overview of past, current and planned audits.

Measures management for medical devices with roXtra measures

Structured action management is essential for eliminating deviations, minimizing risks and complying with quality standards such as ISO 9001, ISO 31000 or industry-specific requirements. With roXtra measures, immediate, corrective and preventive actions (CAPA) can be efficiently planned, implemented and tracked.

Thanks to a digitally supported system, you always have an overview of open, ongoing and completed measures and ensure complete documentation. This allows you to sustainably improve process efficiency, increase product and service quality and meet regulatory requirements.

Your advantages with roXtra measures:

- Central management - clearly record, control and prioritize all measures.

- Automatic effectiveness check: Sustainable implementation through planned controls and tracking.

- Simple evaluation: Filter lists of measures and export them as Excel, Word or PDF.

- Cross-module linking - for consistent and transparent documentation throughout the entire QM system.

Support for quality management and certifications

Our software solutions support you in efficiently operating your quality management system (QMS) in the industrial and service sectors and successfully mastering certifications and re-certifications. With roXtra, you can implement a wide range of standards and regulations efficiently and in compliance with the rules - from ISO 9001 to ISO 27001.

Quality management in industry and services

- ISO 9001: Globally recognized standard for quality management systems that defines the requirements for a company's processes.

- IATF 16949: Specific standard for the automotive industry that specifies requirements for quality management systems in series and spare parts production.

- ISO 14001: Standard for environmental management systems that helps companies to improve their environmental performance.

- EN 9100: Quality management standard for the aerospace industry, which is based on ISO 9001 and takes additional requirements of this industry into account.

- ISO 27001: Standard for information security management systems (ISMS), which describes the requirements for the establishment, implementation, maintenance and continuous improvement of an ISMS.

Risk management and security

- ISO 31000: Guidelines for effective risk management that provide a framework and process for identifying, assessing and addressing risks.

- ONR 49000 / ONR 49001: Austrian standards for risk management systems that provide requirements and instructions for implementing risk management in organizations.

- KonTraG and Section 91 (2) AktG: German legal requirements that oblige listed companies to set up a risk management system in order to identify risks that could jeopardize the company's continued existence at an early stage.

One software, many application areas.

What is a quality management system (QMS) for industrial companies?

A quality management system (QMS) for industrial companies is a structured method for ensuring consistent product and process quality. It comprises defined standards, procedures and controls to comply with standards such as ISO 9001 or IATF 16949, avoid errors and increase efficiency. A QMS helps to minimize risks, reduce production downtime and increase customer satisfaction. Digital solutions such as roXtra enable companies to automate their quality management, optimize processes and ensure transparent, standard-compliant quality assurance.

Do industrial companies have to provide evidence of a QMS?

In many industries, industrial companies are legally or contractually obliged to provide evidence of a quality management system (QMS), especially if they are required to be certified in accordance with ISO 9001, IATF 16949 or other industry-specific standards. Customers and business partners also often demand proof of a functioning QMS in order to ensure consistently high product and service quality. Even if there is no direct obligation, a QMS brings benefits such as more efficient processes, lower error rates and greater competitiveness.

What is the aim of a QM system according to ISO 9001?

According to ISO 9001, the main objective of a quality management system (QMS) is the continuous improvement of processes, products and services in order to increase customer satisfaction. It should ensure that companies work efficiently, minimize risks and meet legal and industry-specific requirements. The standard also promotes a process-oriented way of thinking in order to systematically plan, implement and monitor quality objectives.

Do I have advantages for my QMS through software?

Yes, software for your quality management system (QMS) offers numerous advantages. It automates and optimizes processes, reduces sources of error and ensures efficient management of documents, audits and measures. It also improves traceability, increases process efficiency and facilitates compliance with standards such as ISO 9001. In industry in particular, companies benefit from powerful QM software that digitizes quality management processes and makes them compliant with standards. Digital solutions such as roXtra save companies time, reduce costs and increase transparency throughout the entire quality management process.

How can we ensure that all employees are trained and involved in the quality processes?

To ensure that all employees are trained and integrated into the quality processes, companies should rely on a structured training strategy. This includes regular training, easily accessible work instructions and digital documentation of qualifications. QMS software such as roXtra can help to manage training records, identify knowledge gaps and ensure that every employee is always informed about current quality standards. In addition, feedback processes and an open quality culture encourage employee engagement and accountability.

Examples: Mechanical engineering companies | automotive suppliers | chemical production

More efficient production processes thanks to automated document control

A medium-sized mechanical engineering company had difficulties managing current work and test instructions centrally. Outdated versions led to production errors and increased rejects.

➡ With the introduction of QM software with document control, all documents were centrally managed, automatically versioned and digitally released.

The result: fewer errors, reduced rework and smoother ISO 9001 certifications.

Improved audit and action tracking in the automotive supply industry

An automotive supplier regularly carried out internal and external audits, but tracking corrective and preventive actions (CAPA) was time-consuming and error-prone.

➡ With the new QM software for audit and action management, actions could be planned digitally, responsibilities clearly assigned and automatic reminders set.

Result: faster implementation of audit actions, fewer deviations and improved compliance with IATF 16949.

Risk management and compliance in chemical production

A company in the chemical industry needed to identify risks at an early stage in order to prevent accidents and environmental violations. Before the introduction of QM software, risks were documented manually, which led to delayed response times.

➡ With a digital risk management solution, risks were systematically assessed, measures implemented in real time and regular effectiveness checks integrated.

Result: fewer safety-related incidents, improved compliance with ISO 14001 and greater occupational safety.

roXtra supports you with the following solutions:

We will show you roXtra in a free and non-binding online presentation.